1. Typical Applications +

- Dopant activation and annealing

- Oxidation and nitridation

- Metal alloying and contact anneal

- Stress relief annealing

- Material research and process development

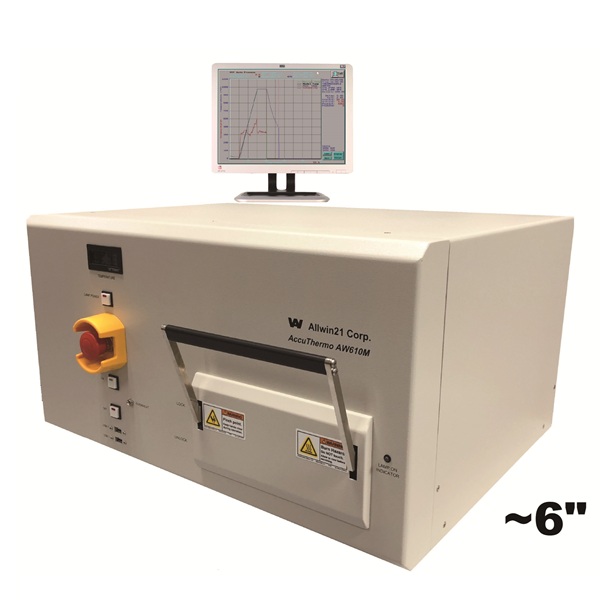

2. Basic Configuration +

- AccuThermo AW610M chassis

- Embedded industry computer board with Allwin21 software package

- Oven control PCB and gas control PCB inside the chassis

- Atmospheric cold-wall aluminum chamber with gold plating and water-cooled passages

- Top and bottom 21 Ushio infrared lamp heating system

- 6 zones with SSR lamp control architecture

- 6 gas lines with 1 of N2 MFC, 10SLM

- Quartz isolation tube

- Quartz tray for 3–6 inch wafers and/or susceptors

- Thin K-type thermocouple (150–840 °C)

- 1 package of K type TC wire, 5 pieces for spare

3. Options & Configurations +

- 6 gas lines with up to 6 of MFCs

- Graphite susceptor with CVD SiC coating

- Non-contact ERP pyrometer for 450–1250°C

- TC wafers for ERP calibration

- Double O-ring chamber sealing

- GEM / SECS interface

4. AW610M Key Advantages +

- Quality – Reliable, High-Performance Process. Combines AG Associates hardware with Allwin21-developed software featuring real-time control, fuzzy logic, and millisecond-level precision.

- Cost – Total Ownership Value. Competitive purchase price with cost-effective operation. Minimizes ongoing usage, maintenance, and spare parts expenses.

- Delivery – Fast, Flexible, Reliable. Ensures predictable outcomes, optimized process control, and long-term stability for R&D, pilot production, and process development.

5. Hardware Highlights +

- Aluminum Plate Chamber (45 years proven)

- Scattered Gold Plating (45 years proven)

- Upper and Lower Lamps (45 years proven)

- 0.0125-inch Thick Isolated Quartz Tube (45 years proven)

- Isolated Quartz Tube – easy contamination removal

- 6 Lamp Banks with SSR Control (40 years proven)

- 21 Ushio Lamps – 5–20 years lifetime

- Thin K-type Thermocouples for 150–840°C

- Patented Non-contact ERP Pyrometer for 450–1250°C

- Quartz Tray for 2–6″ Round Substrates

- Graphite Susceptor with CVD SiC Coating

- 6 Gas Lines with 1 MFC (Upgradeable to 6)

6. Software Highlights +

- Real-Time Closed-Loop Temperature Control with fuzzy algorithms

- Advanced Pyrometer Calibration with dual calibration datasets

- User-Friendly GUI with role-based access

- Customizable Recipe Parameters for RAMP and Steady phases

- Unique PowerSum Monitoring for process supervision and wafer protection

- Lamp Bank Monitoring and control for uniformity optimization

7. Technical Specifications +

- Wafer sizes: 2″–6″

- Ramp up rate: 10–120°C/sec

- Steady duration: 0–300 sec

- Ramp down: 10–200°C/sec

- Temperature range: 150–1150°C (Max 1250°C)

- ERP Pyrometer accuracy: ±1°C

- Thermocouple accuracy: ±0.5°C

- Temperature repeatability: ±0.5°C wafer-to-wafer

- Temperature uniformity: ±5°C across 6″ wafer

- Process gases: N2, O2, Ar, He, forming gas, NH3, N2O2

8. Why Choosing the Right RTP System Is Critical +

- RTP performance cannot be judged by datasheets alone.

- Many RTP tools lack real process repeatability.

- True RTP performance requires proven technology.

- Vacuum RTP adds complexity without real advantage.

- Used RTP systems carry hidden risks.

- High-end RTP systems are often cost-inefficient.

9. Frequently Asked Questions +

1. How does PowerSum help protect valuable wafers? – PowerSum represents integrated thermal energy and ensures process repeatability.

2. Why atmospheric RTP instead of vacuum RTP? – Atmospheric RTP avoids slow cooling and contamination risks.

3. Can AW610M be used for production? – Yes, for R&D and pilot production with proper configuration.

4. When should a furnace be used instead of RTP? – For long-duration equilibrium-driven processes.

10. Product Video +