Manufacturer: Allwin21 Corp.

Condition: New

Wafer Size: 2″ – 6″ Capability

Wafer Loading: 3-axis Robot; Stationary Cassette Plate (Video)

Plasma Power: 600W Air-Cooled RF 13.56MHz

Type: Parallel/Single Wafer Process; Stand-Alone

Gas Lines: 1-3 Lines MFCs. Typical gases are 5 SLM O2, 500 SCCM O2,1000 SCCM N2.

Main Customers: Link

Free Fast Quote: Link

Downloads: AW-105R (PDF)

AW-105R Plasma Asher Descum Features:

- Designed with III-V Production in mind!

- The wafer transport robot installed is much more reliable than the original “frog‑leg” robot.

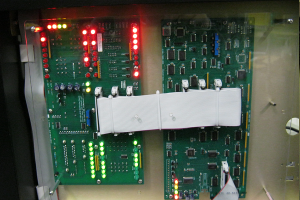

- The control boards were redesigned with modern components and added features.

- The temperature control system for heating the chuck uses the Eurotherm controller. If the software detects the temperature is not within tolerance, it will turn off the current to the chuck heater and abort the process.

- Designed for 2” to 6” circular wafers.

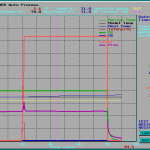

- A light spectrum monitor (optional) is used to determine the endpoint by monitoring the illuminated intensity of the plasma.

- Wafer centering/cooling station.

- NO OBSOLETE PARTS.

- Industrial grade computer, touch screen GUI, and large hard disk drive.

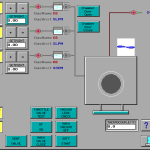

- Footprint is nearly the same as the Matrix 105 (see image…).

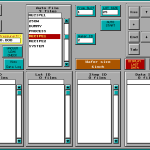

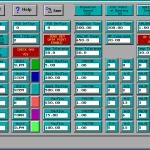

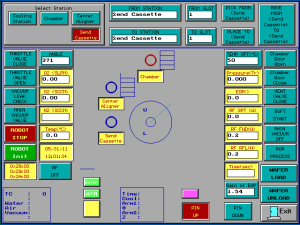

Allwin21 Software Features

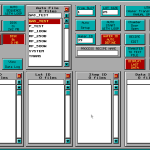

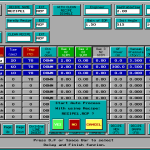

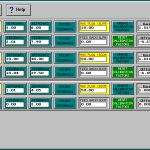

The AW-105R system is controlled by menu commands from the control software. The software allows a great deal of flexibility and control of the AW105R.

The control software features the following:

- Automated calibration of all subsystems from within the control software. This allows faster, easier calibration, leading to enhanced process results.

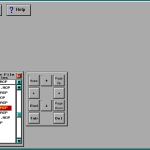

- Recipe creation. It features a recipe editor to create and edit recipes to fully automate the processing of wafers inside the chambers.

- Validation of the recipe so improper control sequences will be revealed.

- Storage of multiple recipes, process data and calibration files so that process and calibration results can be maintained and compared over time.

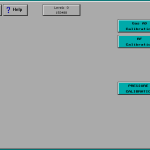

- Passwords provide security for the system, recipe editing, diagnostics, calibration, and setup functions.

- Simple and easy to use menu screens which allow a process cycle to be easily defined and executed.

- Troubleshooting features which allow engineers and service personnel to activate individual subassemblies and functions independently of other subsystems.

- The control software runs on almost any Pentium class PC computer with a parallel (printer) port. The computer interfaces to the AW105R system with only 1 cable, the control interface cable. There is also an interface cable to the robot controller. There is also an interface cable for the Eurotherm controller.

- The interface board inside the machine that translates the computer commands to control the machine has a watchdog timer. If this board looses communication with the control software, it will shut down all processes and halt the system until communication is restored.

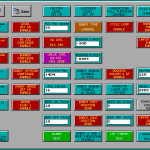

Safety Features

The Allwin21 system incorporates several features to prevent damage to wafers or injury to personnel.

- There is a watchdog timer on the interface board. This turns off the process parameters if the communication between the computer and the system is interrupted or the software freezes.

- The RF system is interlocked to prevent their inadvertent operation when the chamber door is open.

- Pneumatic: The pneumatics is used to operate the Positive Shut-off valves and the chamber door. If there is no air pressure, the shut-off valves will close. If the power is removed from the Allwin21 system, then the pneumatic gas valves close automatically.

- EMO (Emergency Off): When the EMO is depressed, the power to the entire machine is turned off.

- Water Flow Switch: The water needs to flow at the recommended rate that is specified in the Installation manual. When a process starts, it will check the water flow rate. If the flow rate drops below this, the process will not run and an alarm will be issued.

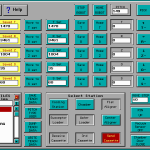

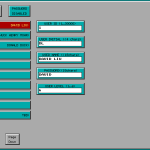

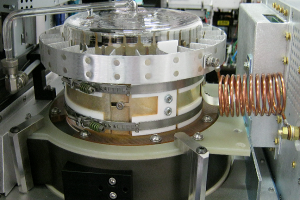

AW-105R Plasma Asher Descum System Overview: The AW-105R represents the industry standard in single-wafer photoresist removal and the mainstay of the highly successful plasma descum system for GaAs. Developed in cooperation with many of the world’s leading GaAs IC producers, the AW-105R has been designed for optimum performance, non-parts obsolescence, and low cost of ownership. The AW-105R is a plasma ash/descum system with an integrated robotic wafer transfer engineered for fragile substrates. It is controlled by our advanced Allwin21 AW-105R Control Software. It is uses RF generated plasma to ash the photoresist. The wafers to be processed are in a cassette and placed on the cassette station. The operator selects a recipe and starts the process run. The robot (Video) takes a wafer from the cassette and places it on the centering station. It then places the wafer into the chamber. Once the wafer has been processed, it is returned to the cassette. Compared with other plasma asher descum systems, the AW-105R is more robust, more reliable and to modernize many of the key electronic components. The AW-105R control software is an advanced control software for the AW-105R system. This document provides a general discussion of the function and calibration of the control software. The AW-105R control software allows full control and diagnostics of the AW-105R system. It allows the creation of recipes for automated control of all aspects of the process. In addition, the operator has the ability to calibrate the system from within the software, and save all process data for later review. The control software uses a set of operating instructions known as recipes to automatically control the Allwin21 system. These recipes are created by the Process Engineer to monitor and control the parameters of the processing cycle. The Operator then uses the software to select and run the process parameters (steady state temperature, process time, ramp rates, RF level, vacuum, etc.). The process periods are typically 1-600 seconds in duration, although periods of up to 9999 seconds can be programmed. The AW-105R control software is also used to create, delete, copy, modify and store the recipes and to execute system diagnostics. There is a large hard drive in the computer, so an almost unlimited number of recipes and process data can be stored. The process data can later be retrieved and taken to a desktop computer for viewing and importing into reports. AW-105R Plasma Asher Descum Systems Applications :

1. Reactor Chamber 2. Wafer Sizes(Customized) 3. Gas Control 4. Substrate Positioning 5. Pressure Control 6. Display 7. Control Systems : Advanced AW Software control the following. 8.Power Supply Module Features 9.Integrated Solid Robot (Video) The Diamond series atmospheric robots represent a significant engineering advancement in the design and reliability of wafer handling equipment.Benefiting from technologically superior components, the robots utilize ultra low inertia, high-response brushless servomotors coupled with zero-backlash Harmonic Drive® gears to achieve greatly enhanced dexterity and precision.AW-105R Plasma Asher Descum Basic Configuration:

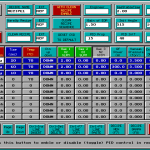

Typical Process and Performance Rate: 1.5um/min at 30 sec partial strip Uniformity: ±5% (max-min) 6mm edge exclusion. Temperature: 250 ºC (±5 ºC) Process Parameters and condition: Pressure: 4.0 torr Power: 425w Gas Flow: O2 1.75 liters Resist Type: AZ1350J Thickness:1.5um Bake Temp:120 ºC Performance Specifications Pressure : 3.0 to 5.0 torr Power: 250-475W Flow: 1.0-2.5 liters O2 Endpoint: Diode array CV: Mobile Ion: 10 Vt 0% total shift on 98% of points ,tested, no shift >5%AW-105R Plasma Asher Descum System Specifications:

AW-105R Plasma Asher Descum Gallery:

AW-105R Plasma Asher Descum Equipment Facilities Requirements:

11.8”Hg(-5.8psi) / 0.1CFM airflow

Some customers for your reference.

| Customer | Country |

| National Research Council Canada | Canada |

| 3SP Technologies S.A.S | France |

| OMMIC | France |

| Semi-Conductor Laboratory | India |

| EPISTAR | Taiwan |

| NCSIST | Taiwan |

| TSMC | Taiwan |

| UMC/Wavetek | Taiwan |

| Wavetek Microelectronics Corp. | Taiwan |

| Win Semiconductor | Taiwan |

| Lumentum Technology UK Limited | UK |

| Continental Automotive Systems Division | USA |

| Finisar Coherent | USA |

| RTI International | USA |

| SKYWORKS SOLUTIONS | USA |

| Standford University | USA |

| Qorvo – TriQuint Semiconductor Texas | USA |

| UC Lawrence Berkeley Lab | USA |

Matrix and related trademarks belongs to Matrix company.

AW-105R Spare Parts list for your reference.

| Item | P/N | Description |

| 1 | 0990-95010 | LAMP,PUSHBUTTON SWITCH |

| 2 | 0995-16521 | SOLENOID, ETO-3 |

| 3 | 0995-16527 | SOLENOID, ET-2M |

| 4 | 0101-0484 | ASSY, BELLOWS COMPRESSION |

| 5 | 0992-60149 | INSULATOR, BELLOWS MACOR |

| 6 | 0994-60005 | O’RING,RED SILICONE (door) |

| 7 | 0994-60006 | O’RING,RED SILICONE (reactor) |

| 8 | 0994-60007 | O’RING,RED SILICONE (bell jar) |

| 9 | 0994-60019 | O’RING,VACUUM VALVE |

| 10 | 0994-60029 | O’RING,VAC. VALVE POPPET |

| 11 | 0994-60050 | O’RING, CHUCK SEAL |

| 12 | 0994-60055 | O-RING SILICONE (lifter pins) |

| 13 | 0994-60062-AW | O-RING KALREZ (lifter pins) |

| 14 | 0994-60063 | O-RING KALREZ (chuck) |

| 15 | 0995-10597 | CYLINDER, PANCAKE |

| 16 | 0992-60094 | Ceramic Ring |

| 17 | 0992-60126 | Insulator, Lower Reactor |

| 18 | 0992-60135 | Pin Wafer Lifting |

| 19 | 0992-60147 | Chamber |

| 20 | 0992-60253 | Baffle, Qtz. Insulated Reactor |

| 21 | 0995-16512 | Bleed Valve |

| 22 | 0995-99777 | Door Cylinder |

| 23 | 0995-99752 | Baratron,0-10Torr, VCR 1/2″ |

| 24 | S2100-1008-008 | PCA, Main Control Board |

| 25 | S2100-0105-019 | PCA, Robot Control Board |

| 26 | S2100-0105-010 | PCA, Distribution Board |

| 27 | 0995-99752 | Baratron,0-10Torr, VCR 1/2″ |

| 28 | A5-0602-A | Computer Board |

| 29 | A5-0603-A | CF Card, 64G |

| 30 | A5-1021 | Memory, 256M.DDR333.200PIN, Non-ECC |

KEYWORDS: Plasma Asher, Plasma Descum, Dry Clean, Semiconductor Equipment, Used Semiconductor Equipment, Semiconductor Process Equipment, Matrix 105, Matrix 205, Matrix 303, Matrix 403,Matrix 106,Matrix 104, Matrix 102,Matrix 101, Matrix 10, System One Stripper, Model 105, System One Etcher, model 303, model 403,Matrix 1107, Plasma Asher, Plasma Descum, Dry Clean, Semiconductor Equipment, Used Semiconductor Equipment, Semiconductor Process Equipment, Branson/IPC 2000, Branson/IPC 3000, Branson/IPC 4000, Barrel Asher, Barrel Etch, Barrel Etcher, Plasma Asher, Plasma Descum, Dry Clean, Downstream Asher,Semiconductor Equipment, Used Semiconductor Equipment, Semiconductor Process Equipment, Gasonics Aura 1000, Gasonics Aura 2000, Gasonics Aura 3000, Gasonics L3510, Gasonics Aura 3010 ,Plasma Etcher, Plasma Etching, Dry Etching, Dry Clean, Semiconductor Equipment, Used Semiconductor Equipment, Semiconductor Process Equipment, Plasma RIE ,Reactive Ion Etch System, Reactive Ion Etch System, Tegal 901e, Tegal 903e, Tegal 901e TTW, Tegal 915,Tegal 701,Tegal 703,Tegal 801,Tegal 803,Tegal 981e,Tegal 903e, Plasma Etcher, Please Etching, Dry Etching, Dry Clean, Semiconductor Equipment, Used Semiconductor Equipment, Semiconductor Process Equipment, Lam AutoEtch 490, Lam AutoEtch 590, Lam AutoEtch 690, Lam AutoEtch 790, Lam Rainbow 4400, Lam Rainbow 4420, Lam Rainbow 4428, Lam Rainbow 4500, Lam Rainbow 4520, Lam Rainbow 4528, Lam Rainbow 4600, Lam Rainbow 4620, Lam Rainbow 4628, Lam Rainbow 4700, Lam Rainbow 4720, Lam Rainbow 4728,Plasma Etcher, Plasma Etching, Dry Etching, Dry Clean, Semiconductor Equipment, Used Semiconductor Equipment, Semiconductor Process Equipment, Gasonics AE 2001, Microwave Etcher, Microwave Plasma Etcher, Microwave Etch, Downstream Plasma Etch