Product Description

Part Number: 853-6534-2

Description: 853-6534-2, Gate Drive Cylinder

QTY Recommended: 1

Where Used: 853-1201-2 , Bottom Plate Exit(1x)

Manufacturer Number: 853-6534-2

[contact-form-7 404 "Not Found"]

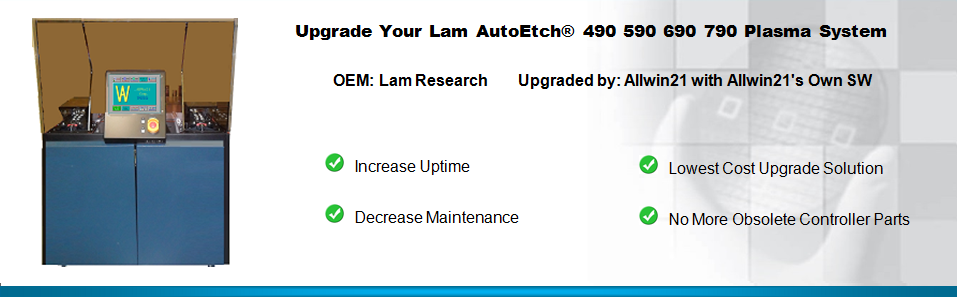

The Upgrade kit for Lam AutoEtch X90 ( Lam AutoEtch® 490 590 690 790 ) includes an advanced AW-590 System Control with touch screen operator interface or 17″ LCD Monitor , New PC with Allwin21 AW-590 software and new interface board. The kit is easy to incorporate (plug-and-play) into the original Lam AutoEtch Etch systems. No need to move the to be upgraded system from its present location. All utility connections stay in place. The new control system will enhance the entire system operation. It makes the upgraded plasma Etch system much more reliable with real time precise control.

AW-590 System Control Key Features

- Maintenance, Manual, Semi Automatic and Full Automatic operation modes

- Automated calibration of all subsystems

- Trouble shooting to sub-assembly levels

- Programmed comprehensive calibration and diagnostic functions

- Recipe creation for full automatic wafer processing

- Automatic decline of improper recipes and process data

- Multi level password protections

- Storage of multiple recipes and system functions

- Real-Time process data acquisition,display ,analysis

- Real-Time graphics user display (GUI)

- Process Data and Recipe storage on a hard drive

- Easy TC vacuum gauge calibration with using software, not the hardware resistors adjusting.

- Advanced EOP function with SLOPE

Replaced Obsolete Parts

- The old controller

- The old Interface Board

Fast On-site Upgrading

- Customized survey and upgrading plan

- Same input/output connectors

- Same definition of each connector

- Plug-and-Play

Allwin21 Corp. has been focusing on providing solutions and enhancements to Lam AutoEtch 490 ,Lam AutoEtch 590, Lam AutoEtch 690, Lam AutoEtch 790, Lam Rainbow 44XX, Lam Rainbow 45XX, Lam Rainbow 46XX, Lam Rainbow 47XX used plasma Etch RIE semiconductor process equipment. These OEM Etch RIE semiconductor equipment have been used in productions and R&D since 1990′s. They have been proven to be a true “work horse”. Allwin21 Corp. can customize these OEM systems with Allwin21′s comparable integrated process control system with PC and new critical components to achieve the goal of giving our customers a production edge with right cost.

|

Models |

AutoEtch |

|||

|

490 |

590 |

690 |

790 |

|

|

System Type |

Fully automated ,in-line, single wafer, double airlocked, parallel plate plasma |

|||

|

Plasma Etcher |

||||

|

Wafer Size |

4”,6” |

|||

|

Controller |

Z80 Microprocessor * |

|||

|

Recipe |

A recipe programmable module |

|||

|

Etch Material |

Poly Si, Nitride |

Oxide |

Metal |

Metal |

|

Chamber Heater (Upper,Lower) |

No |

No |

Yes |

Yes |

|

Loadlock and Chamber door |

From inside, easy leak |

|||

|

Gas System |

5 MFCs with 6 gas lines |

|||

|

Cooling |

Chiller |

|||

|

Clamp with He cooling |

No |

|||

|

Electrode Gap |

0.5cm ~ 2.7cm, Potentiometer |

No |

||

|

Wafer Transfer |

Belt, no detector, no aligner (with wafer block) |

|||

|

Plasma Load lock |

No |

Optional (LPG-6) |

||

|

Atmospheric Passivation Module |

No |

|||

|

RF Match |

Upper |

Lower |

||

|

RF Split |

No |

|||

|

RF Generator |

13.56 MHz |

|||

|

Dimension (Etcher System only) |

44″ W x 36″D x 46″H |

|||

|

Weight (Etcher System only) |

950 Lbs |

|||

|

* Allwin21 Corp. provides upgrade kits including computer, AW Software( GUI), Touch Screen, New Interface Board and New EOP technology |

||||