Why upgrade your old used semiconductor process equipment ?

-

Low cost solution of obsolete components and parts.

- Use new air cooling RF generator to replace the obsolete water cooling RF Generator, avoiding water flood in Fab/Lab.

- Use new integrated solid robotic wafer transfer to replace the obsolete index/frog robotic wafer transfer

- Requirement of stability of the system

- Requirement of network function (GEM/SECSII).

- Requirement of PC control for data storage.

- Requirement of GUI.

- Requirement of more precise control.

- Requirement of better repeatability, uniformity.

- Requirement of easier maintenance, calibration, and trouble shooting.

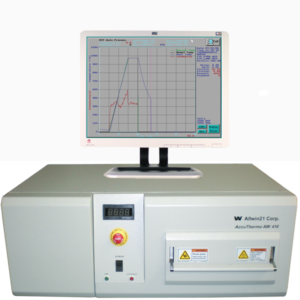

Allwin21 Corp. has been focusing on providing solutions and enhancements to the following used semiconductor equipment. These OEM semiconductor equipment have been used in productions and R&D since 1990′s. They’ve each been PROCESS-PROVEN. Allwin21 Corp. can refurbish and/or upgrade these OEM systems with Allwin21′s comparable integrated process control system with PC, solid 3-axis robotic wafer transfer system (if applicable), and new critical components to achieve the goal of giving our customers a production edge with right cost.

We have been doing upgrade for many production proven equipment, such as Perkin-Elmer 2400, Perkin-Elmer 4400, Perkin-Elmer 4410, Perkin-Elmer 4450, Perkin-Elmer 4480, Matrix 105 , Matrix 106, Matrix 303, Matrix 303, Matrix 403, Matrix 205, Matrix 101, Matrix 102, Matrix 103, Matrix 104,Tegal 901e, Tegal 903e, Lam Research LAM AutoEtch 490, Lam AutoEtch 590, Lam AutoEtch 690, Branson/IPC 2000, Branson IPC 3000, Branson/IPC 4000, Gasonics Aura 3000, Gasonics Aura 3010, Gasonics L3510, Gasoncis Aura 1000, Gasonics AE 2001, AG Associates Heatpulse 610, AG Associates Heatpulse 410, AG Associates Minipulse 310, AG Associates Heatpulse 210 on the field for many cases. The reliability have been improved a lot for most of the tools after upgrading. We designed the upgrade kits for these working tools that can do plug and play and most of them only need 2 to 3 days include training. For PE sputter, since it is a little complicated, but we still target to upgrade within one week include training if the machine without other problems.

|

|

|

|

| Gasonics Aura 3000 3010 Gasonics L3510 | LAM AutoEtch 490 590 690 790 |

|

|